Add to Cart

Gypsum Board Steel Frame Drywall Steel Runner And Stud Making Machine With 3T

1. Technical Parameter

| Item NO |

Description |

Offered specification |

| 1.1 | Roller stations | About 13 stations |

| 1.2 | Voltage | 380V, 50HZ, 3phase or customized |

| 1.3 | Raw material | Galvanized steel |

| 1.4 | Rolling thickness | 0.35-1.2mm |

| 1.5 | Dimension | 4500×800×1200(mm) |

| 1.6 | Main motor power | 7.5kw |

| 1.7 | Roller material | 45# steel, coated with chrome, Quenching |

| 1.8 | Shaft diameter | Φ60mm ,material is 45# forge steel |

| 1.9 | Transmission | By chain 1 inch |

| 1.10 | PLC | Delta brand or Panasonic |

| 1.11 | Material of chain | 45# forged steel with frequency quenching, 12A |

| 1.12 | Material of cutting | Cr12Mov with quench HRC58-62° |

| 1.13 | Tolerance | +-1.5mm |

| 1.14 | Weight | 3 Tons |

2. Machine Components

| 3Tons decoiler | 1 set |

| Hydraulic Cutting | 1 set |

| Main roll forming machine | 1 set |

| Control box system | 1 unit |

| Out tables | 1 unit |

| Safety cover | 1 unit |

| Tool box | 1 package |

3. Features of the production line

1) Directly input the data on the touchable screen, it is easy operation.

2) Automatically continually manufactures high quality product with PLC.

3) Saving time and cost owing to high speed running with hydraulic system.

4) Professional designing for manufactures roofing & walling

5) Unit one, one power wire to operate

6) Hydraulic station and main motor is under machine frame to save space

4. Application

Interior non-load-bearing walls

Floor joists and headers

Rafters, purlins, and girts

Non-load-bearing exterior curtain walls

Axial load-bearing interior and exterior walls

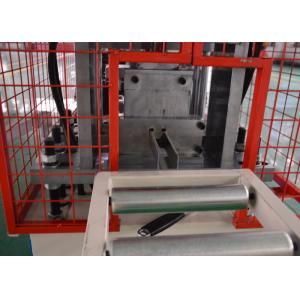

5. Machine picture